Ontario service representative for Armstrong Plate & Frame and Shell & Tube Exchangers.

Ontario service representative for Caron et files Custom Industrial Heat Exchangers, Heater Coils, Steam Unit Heaters

Ontario service representative for Bray Butterfly Valves, Bray Ball Valves, Bray Check Valves, Bray Knife Gate Valves, Bray Actuators – Electric, Manual & Pneumatic Solenoids

Ontario service representative for Puroflux line of Permanent Media Filters, Centrifugal Separators and Disc Filters.

Ontario service representative for Filter Solutions Inc. line of Magnetic Separators, Bag and Cartridge Housings and Wedge Wire Filters & Strainers.

Ontario service representative for REOTEMP Instruments line of Pressure Gauges, Bi-Metal Thermometers and RTDs

Ontario service representative for Clearstream Filters line of Self-Cleaning Indexing Media Filters and Custom Filter Bags

Ontario service representative for Xylem, Bell & Gossett Plate & Frame and Shell & Tube Exchangers. Ontario Service representative for TTP (API Heat Transfer Company) Oil Coolers.

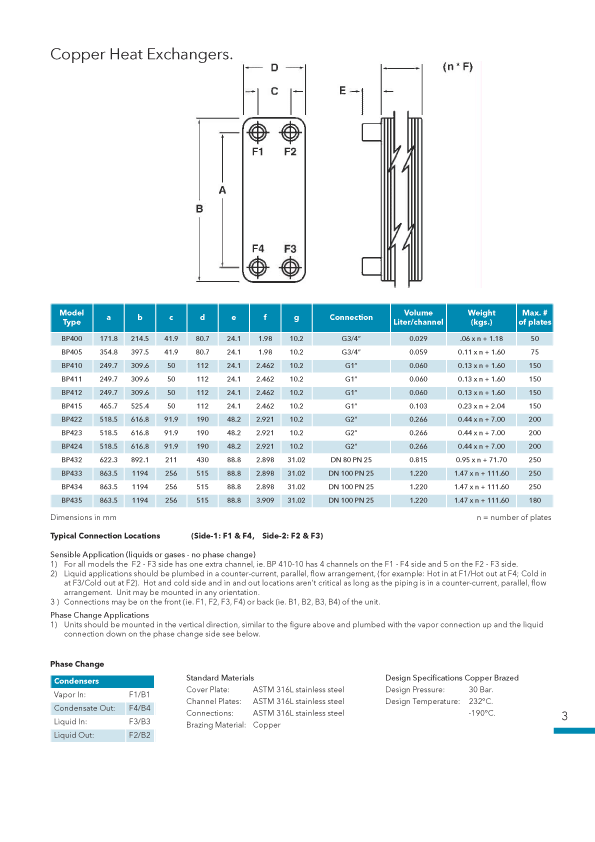

Ontario Service representative for SWEP (A Dover Company) Brazed Plate Heat Exchangers.

Ontario Service representative for Kelvion Brazed Heat Exchangers, Plate & Frame Heat Exchangers, and Shell & Tube Heat Heat Exchangers.

WHEN SHOULD A PLATE & FRAME HEAT EXCHANGER BE SERVICED?

As a heat exchanger becomes fouled with dirt, debris or scale, often the modulating valve provides additional hot or cold liquid to help compensate for the loss of efficiency of the heat exchanger.

Over time the control valve will continue to open fully. Unfortunately, on the hottest or coldest days, even with the valve fully open the heat exchanger cannot meet the thermal transfer requirements and the situation becomes critical.

Monitoring just the operating temperature provides a false sense of security. Recording the difference in the outlet and inlet pressures provides a more accurate result of the amount of fouling.

Fouling equal to the thickness of a piece of paper represents a 20% loss of thermal efficiency. In addition, the energy cost for pumps increases since the pump must work harder to overcome the increased pressure resistance through the PHE

Can PHEs Be Cleaned Using High Pressure Water?

Plate heat exchangers (PHEs) are vital for efficient heat transfer in industries like HVAC, food processing, and power generation. Fouling from scale, rust, or organic matter can reduce their performance, increasing energy costs and risking system downtime.

A common question is: Can PHEs be cleaned using high pressure water?

Yes, high-pressure water jetting is an effective cleaning method for PHEs, particularly for stubborn fouling, but it requires careful execution to avoid damaging delicate components. Industry experts like T.H. Industrial Solutions provide specialized services to ensure safe and effective cleaning.

What Is High-Pressure Water Cleaning for PHEs?

High-pressure water jetting uses a concentrated stream of water, typically at pressures up to 2,500 bar (36,000 psi), to dislodge tough deposits like scale, marine fouling, or debris from PHE plates. This method is particularly effective for severe fouling that Clean-in-Place (CIP) or chemical flushing cannot fully address, such as mussels or hardened calcium carbonate, as noted in industrial application

Effectiveness of High-Pressure Water Cleaning

High-pressure water cleaning is highly effective for PHEs because it:

- Removes Stubborn Deposits: The forceful water stream clears scale, rust, and biological fouling, restoring heat transfer efficiency, as emphasized by Total Heat Exchanger Solutions for industrial applications.

- Targets Complex Geometries: It reaches tight spaces and intricate plate designs, ensuring thorough cleaning.

- Reduces Chemical Use: High-pressure jetting minimizes reliance on chemicals, making it environmentally friendly when wastewater is properly managed

- Heat Exchanger Ontario uses a 10 hp gas pressure washer to clean PHE plates, effectively removing dirt and biofilm, though it may be less effective for scale and rust buildup compared to chemical methods.

How High-Pressure Water Cleaning Works

- Disassembly: PHEs are often disassembled to access plates, as high-pressure cleaning typically requires manual or semi-automated application, per industry standards.

- Jetting: Technicians use high-pressure water jets to clean plates, as offered by Heat Exchanger Ontario, ensuring debris is dislodged without damaging surfaces.

- Inspection: Post-cleaning checks, such as dye penetrant testing, ensure plates are free of cracks or pinholes, a practice emphasized by Heat Exchanger Ontario

- Waste Management: Wastewater is collected and treated to meet environmental regulations

Limitations of High-Pressure Water Cleaning

- Risk of Damage: Excessive pressure can harm delicate plates or gaskets, especially in stainless steel or titanium PHEs, requiring expert control

- Time-Intensive: Disassembly and cleaning can take 2–3 days per exchanger, as seen in traditional methods, compared to faster CIP methods.

- Wastewater Concerns: High-pressure cleaning generates significant wastewater, increasing disposal costs and environmental impact, as highlighted in industry practices.

Best Practices for High-Pressure Water Cleaning

- Combine with Chemical Cleaning: For severe fouling, pair high-pressure jetting with chemical flushing

- Use Professional Services: Experts ensure proper pressure settings and protect gaskets during cleaning.

- Monitor Wastewater: Proper containment and treatment of runoff water are critical to comply with environmental regulations

- Regular Maintenance: Schedule cleaning every 1–3 years, depending on fouling severity, to maintain efficiency

When to Use High-Pressure Water Cleaning

High-pressure water cleaning is ideal for PHEs with severe fouling, such as marine growth or hard scale, where CIP or chemical methods are insufficient. It’s commonly used in industries like power generation or marine applications. For routine maintenance, CIP or chemical flushing may be preferred to avoid disassembly.

Conclusion

High-pressure water cleaning is an effective solution for cleaning plate heat exchangers, particularly for tough deposits, but it requires expertise to prevent damage and manage wastewater. Companies like T.H. Industrial Solutions offer professional services to ensure safe, efficient cleaning tailored to your PHE’s needs.

Can PHEs Be Cleaned Using Chemical Flushing?

Plate heat exchangers (PHEs) are vital for efficient heat transfer in industrial, HVAC, and marine systems. Over time, PHEs can accumulate scale, rust, or organic debris, which reduces performance and increases energy costs.

A common question is: Can PHEs be cleaned using chemical flushing?

The answer is yes—chemical flushing is a proven and effective method for cleaning PHEs when performed by professionals with the right expertise and equipment.

T.H. Industrial Solutions Inc. (THS) has been servicing industrial plate and frame heat exchangers as with shell and tube heat exchangers. Professionally solving process problems across Canada since 2009. THS head office is located in Pickering, Ontario with a 6,000 square foot service center in Hamilton, Ontario.

Today there are fewer qualified people in this industry that know the products and understand the applications. Utilizing hands on experience and knowledge that has been gained by our THS sales and service technicians for over the past 30 years, we will take the time to understand what you require and strive to provide a prompt, educated and accurate response at a competitive price.

Our Heat Exchanger Cleaning Services, along with heat exchanger gasket replacement systems, and knowledge of heat exchanger gasket materials make THS your Industrial Heat Exchanger Service Solution

HEAD OFFICE

1550 Bayly Street, Unit 15

Pickering, ON L1W 3W1

T 905 831-4963

SERVICE CENTER

76 Harlowe Road, Unit 4 - 7

Hamilton, ON L8W 3R6

T 905 318-0777

F 905-318-8422

Contact THS Service

T. H. Industrial Solutions

Head Office

1550 Bayly Street, Unit 15

Pickering, ON L1W 3W1

T. H. Industrial Solutions

Service Center

76 Harlowe Road, Unit 4 - 7

Hamilton, ON L8W 3R6