SHELL & TUBE

Shell & Tube

Heat Exchanger.

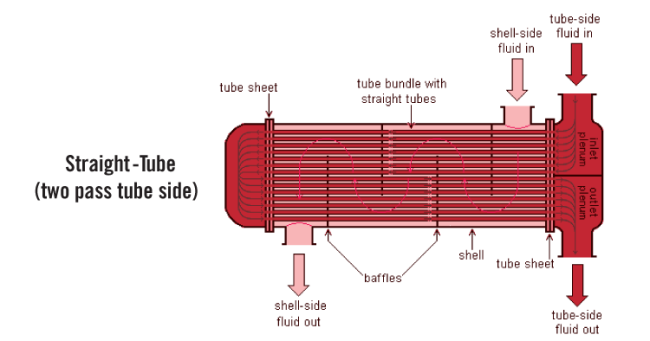

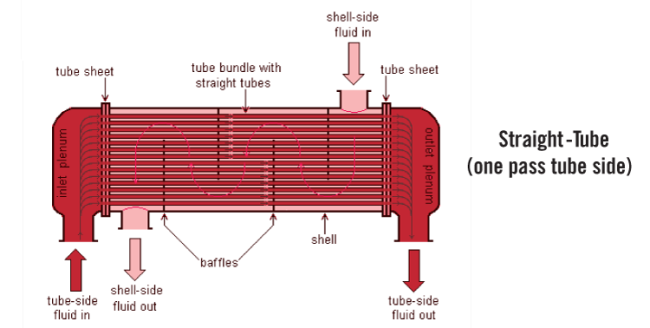

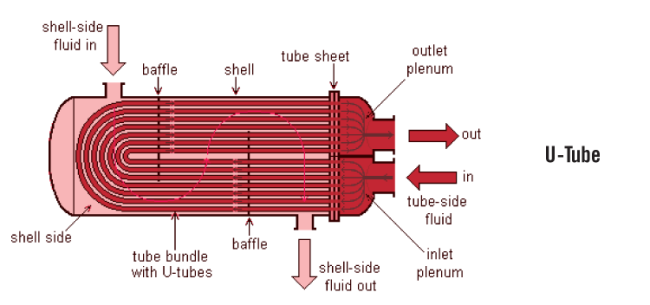

A Shell and Tube is the most common type of heat exchanger used in applications that require higher pressures and temperatures. Consisting of a tube bundle inside a shell, this basic design is heavy duty, rugged and durable. The system is simple, two fluids of different temperatures are circulated through the heat exchanger. One fluid flows through the tubes while another fluid flows over the tubes providing an optimum and efficient heat transfer.

Advantages of a Shell & Tube

Application

Higher pressure and temperature options available

Design

Basic, heavy duty, rugged and durable

Lifespan

Average life is 15-20 years; however it is

not uncommon to be in service for over 30 years

Economical

Typically less expensive than other types of

heat exchangers including a plate and frame

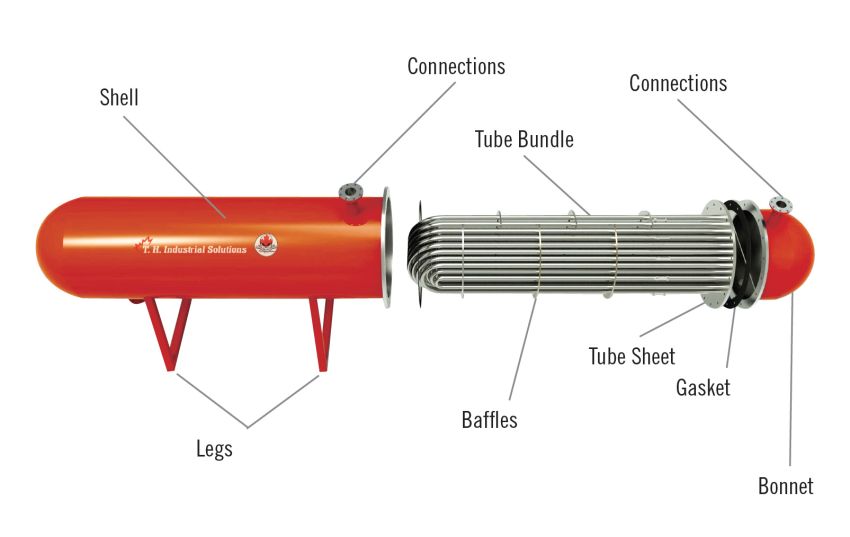

Main Components of a Shell & Tube

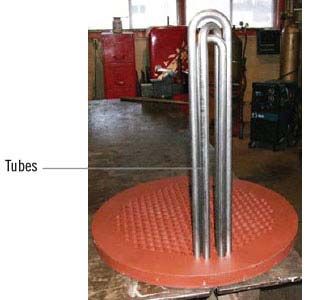

The tubes are typically copper or stainless steel with a ¾" or 5/8" outside diameter, while the remaining components are usually manufactured from milled steel.

Tie rods (circular metal rods) and spacers hold the tube bundle together while holding the baffles in the correct position. The tie rods are fastened into the tube sheet then secured at the farthest baffle. The number of tie rods, baffles and tubes depends on shell diameter and required application.

Applications (Shell & Tube)

Food & Beverage

(Breweries, Dairy, Fruit, Vegetable)

Pasteurization

Sterilization

Evaporation

UHT Treatment

Reception Thermization

Wort Boiling

Sterilization

Evaporation

UHT Treatment

Reception Thermization

Wort Boiling

Industrial

(Automotive, Mining, Pulp & Paper, Sugar)

Water Heating/Cooling

Demineralization

Evaporation

Economizing

Heat Recovery

Quench Oil Cooling

Caustic Solution Heating

Demineralization

Evaporation

Economizing

Heat Recovery

Quench Oil Cooling

Caustic Solution Heating

Energy

(Biofuels, Nuclear, Renewable Power, Oil & Gas)

Heat Recovery

Geothermal

Quench Coolers

Lubrication Oil Cooling

Corrosive Fluid Heating/Cooling

Crude Oil Heating

Diesel Engine Cooling

Auxiliary Cooling

Geothermal

Quench Coolers

Lubrication Oil Cooling

Corrosive Fluid Heating/Cooling

Crude Oil Heating

Diesel Engine Cooling

Auxiliary Cooling

Chemical & Pharmaceutical

(Fertilizers, Petrochemicals, Inorganic Chemicals)

Solvent Heating

Glycol Cooling

Reactor Cooling

Extraction

Fermentation

Fragmentation

Methanation

Glycol Cooling

Reactor Cooling

Extraction

Fermentation

Fragmentation

Methanation

Commercial HVAC

(Hospitals, Condominiums, Shopping Centers)

Domestic Water Heating

Swimming Pool Heating

Free Cooling

Cooling Tower Isolation

Heat Pump Systems

Heat Recovery

Thermal Storage Systems

Swimming Pool Heating

Free Cooling

Cooling Tower Isolation

Heat Pump Systems

Heat Recovery

Thermal Storage Systems

Marine

(Container Vessels, Bulk Carriers, Barges)

Lube Oil Cooling

Auxiliary Power Generation System

Jacket Water Cooling

Central Cooling

Seawater Isolation Exchanger

Engine Oil Cooling

Ventilation Coolers and Heaters

Auxiliary Power Generation System

Jacket Water Cooling

Central Cooling

Seawater Isolation Exchanger

Engine Oil Cooling

Ventilation Coolers and Heaters

Common Shell & Tube Heat Exchanger Designs

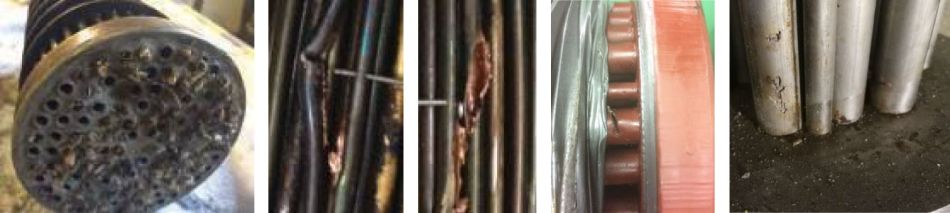

Potential Issues with a Shell & Tube Heat Exchanger

- When vacuum breakers or thermostatic vents are not installed or functional the tube can be sucked in and break.

- If the bundle is subjected to temperature extremes (thermal shock), the tubes will develop spiral cracks.

- On steam applications, harmonics can occur. This constant vibration can cause the steel baffles to eventually cut into the copper tubes.

- Chemical corrosion resulting from interaction between the heat exchanger and the circulated fluids.

- Marine film or coating on tubes such as scale, mud, algae and zebra mussels plugging tubes, this results in higher corrosion and restricts heat flow.