ALFA LAVAL Gaskets

ALFA LAVAL Gaskets

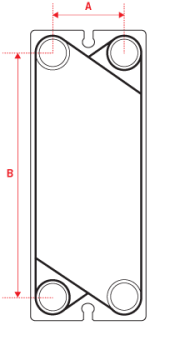

| Model | M3 FM |

M3 FG |

M3 FGL |

M3-X FM |

M3-X FG |

|

| A = mm | 60 | 60 | 60 | 60 | 60 | |

| B = mm | 357 | 357 | 357 | 357 | 357 | |

| Model | M6 FM - FML |

M6 FG - FGL |

M6 FD |

M6M FM - FML |

M6M FG - FGL |

M6M FD |

| A = mm | 140 | 140 | 140 | 140 | 365 | 140 |

| B = mm | 640 | 640 | 640 | 640 | 930 | 640 |

| Model | M6MD * FM - FML |

M6MD * FG - FGL |

M6MD * FD |

M6MW** FM - FML |

M6MW** FG - FGL |

M6MW** FD |

| A = mm | 140 | 140 | 140 | 140 | 140 | 140 |

| B = mm | 640 | 640 | 640 | 640 | 640 | 640 |

| Model | M10 B FM |

M10 B FG |

M10 B FG |

M10 BW** FM |

M10 BW** FG |

M10 BW** FD |

| A = mm | 225 | 225 | 231 | 225 | 225 | 231 |

| B = mm | 719 | 719 | 719 | 719 | 719 | 719 |

| Model | M10 M FM |

M10 M FG |

M10 M FD |

M10 MD* FM |

M10 MD* FG |

M10 MD* FD |

| A = mm | 225 | 225 | 231 | 225 | 225 | 231 |

| B = mm | 719 | 719 | 719 | 719 | 719 | 719 |

| Model | M15 B FML |

M15 B FM8 |

M15 B FG8 |

M15 B FD8 |

M15 E FG8 |

M15 E FD8 |

| A = mm | 298 | 298 | 304 | 304 | 298 | 304 |

| B = mm | 1294 | 1294 | 1294 | 1294 | 1294 | 1294 |

| Model | M15 M FM8 |

M15 M FG8 |

M15 M FD8 |

MK15BW** FM |

MK15BW** FG |

MK15BW** FD |

| A = mm | 298 | 298 | 304 | 298 | 294 | 304 |

| B = mm | 1294 | 1294 | 1294 | 1294 | 1294 | 1294 |

| Model | M20 M FM |

M20 M FG |

M20 M FS |

M20 MW** FM |

M20 MW** FG |

M20 MW** FS |

| A = mm | 353 | 365 | 353 | 353 | 365 | 353 |

| B = mm | 1478 | 1478 | 1478 | 1478 | 1478 | 1478 |

| Model | MX20 B FMS |

MX20 B FGS |

MX20 B FDS |

MX25 B FM |

MX25 B FG |

MX25 B FD |

| A = mm | 439 | 439 | 439 | 439 | 439 | 439 |

| B = mm | 1939 | 1939 | 1939 | 1939 | 1939 | 1939 |

| Model | M30 FM |

M30 FG |

M30 FD |

MA30 W** FM |

MA30 W** FG |

MA30 W** FS |

| A = mm | 596 | 596 | 596 | 561 | 561 | 561 |

| B = mm | 1842 | 1842 | 1842 | 1811 | 1811 | 1811 |