Bell & Gossett Gaskets

Bell&Gossett Gaskets

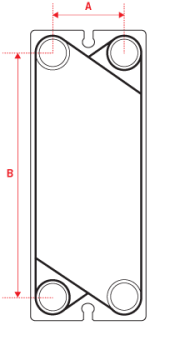

| Model Frame type |

GPX 34P |

GPX 34P FG |

GPX 34P FGL |

GPX 130 FG |

GPX 130 VLCH |

GPX 130 DWFG |

| A = mm | 60 | 60 | 60 | 135 | 135 | 135 |

| B = mm | 357 | 357 | 357 | 591 | 591 | 591 |

| Model Frame type |

GPX 161 |

GPX 161 FG - FGL |

GPX 161 FD |

GPX 151 FM - FML |

GPX 151 FG - FGL |

GPX 151 FD |

| A = mm | 140 | 140 | 140 | 140 | 140 | 140 |

| B = mm | 640 | 640 | 640 | 640 | 640 | 640 |

| Model Frame type |

GPX 237 FM |

GPX 237 FG |

GPX 237 FD |

GPX 258 FG |

GPX 258 BFD |

|

| A = mm | 225 | 225 | 231 | 234 | 234 | |

| B = mm | 719 | 719 | 719 | 703 | 703 | |

| Model Frame type |

GPX 258B FM |

GPX 258B FG |

GPX 258B FD |

GPX 463 FG |

GPX 463 FS |

GPX 646 FM8 |

| A = mm | 225 | 225 | 231 | 290 | 290 | 298 |

| B = mm | 719 | 719 | 719 | 1046 | 1046 | 1294 |

| Model Frame type |

GPX 646 FG8 |

GPX 646 FD8 |

GPX 678 FML |

GPX 678 FM8 |

GPX 678 FG8 |

GPX 678 FD8 |

| A = mm | 298 | 304 | 298 | 298 | 298 | 304 |

| B = mm | 1294 | 1294 | 1294 | 1294 | 1294 | 1294 |

| Model Frame type |

GPX 807 FL |

GPX 807 FG |

GPX 807 FD |

GPX 807 BWGF |

GPX 807 BWFD |

GPX 538 FG |

| A = mm | 350 | 350 | 350 | 350 | 350 | 365 |

| B = mm | 1315 | 1315 | 1315 | 1315 | 1315 | 930 |

| Model Frame type |

GPX 538 FD |

GPX 850 FG |

GPX 850 WGF |

GPX 850 SFG |

GPX 850 DWFG |

GPX 850B BGF |

| A = mm | 365 | 365 | 365 | 365 | 365 | 365 |

| B = mm | 930 | 1450 | 1450 | 1450 | 1450 | 1450 |

| Model Frame type |

GPX 915 FM |

GPX 915 FG |

GPX 915 FS |

GPX 1152 BFL |

GPX 1152 BFG |

GPX 1152 BFD |

| A = mm | 353 | 365 | 353 | 430 | 430 | 430 |

| B = mm | 1478 | 1478 | 1478 | 1550 | 1550 | 1550 |

| Model Frame type |

GPX 1152 BFL |

GPX 1152 BFG |

GPX 1152 BFD |

GPX 1614 FG |

GPX 1614 FD |

GPX 1614 FS |

| A = mm | 430 | 430 | 430 | 439 | 439 | 439 |

| B = mm | 1550 | 1550 | 1550 | 1939 | 1939 | 1939 |

| Model Frame type |

GPC 1700 HBM |

GPX 1700 HA |

GPX 1700 FM |

GPX 1980 FG |

GPX 1980 FD |

GPX 2150 HA |

| A = mm | 540 | 540 | 596 | 596 | 596 | 765 |

| B = mm | 1836 | 1836 | 1842 | 1842 | 1842 | 1850 |